#Cylinderblock: The Engines Unbeatable Heart

#Cylinderblock: The Engines Unbeatable Heart

Unleash the Powerhouse: Discover the Cylinderblocks Essence

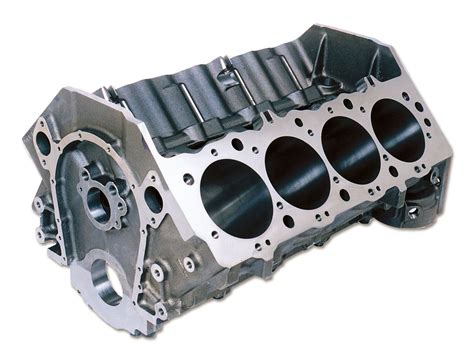

In the realm of automotive engineering, where precision meets performance, the cylinderblock stands tall as the engines indomitable heartbeat. This remarkable component serves as the foundation upon which the engines power and efficiency are built. Carved from a single block of high-strength material, the cylinderblock meticulously houses the cylinders, the combustion chambers, and the intricate system of coolant passages that ensure optimum engine temperature.

Materials and Engineering Marvels

The choice of material for a cylinderblock is paramount. Cast iron, renowned for its exceptional durability and heat retention, has been the traditional choice for decades. However, advancements in metallurgy have introduced a spectrum of alternative materials, each offering unique advantages. Aluminum, with its exceptional heat transfer properties and lightweight nature, has emerged as a popular choice in modern engines. Composite materials, combining strength and weight reduction, represent the cutting-edge of cylinderblock design.

Technology at the Forefront

The modern cylinderblock is a testament to technological prowess. Computer-aided design (CAD) and finite element analysis (FEA) empower engineers to optimize every aspect of the cylinderblocks geometry, maximizing structural integrity and thermal efficiency. Precision machining techniques, coupled with advanced manufacturing processes, ensure that each cylinderblock meets exacting tolerances, ensuring seamless engine operation.

#Lubrication: The Lifeblood of Smooth Performance

Effective lubrication is crucial for the longevity of the cylinderblock and its associated components. A dedicated oil pump circulates a constant stream of oil through the engines intricate network of passages, reducing friction and dissipating heat. Oil filters, acting as vigilant guardians, remove impurities and contaminants, maintaining the oils purity and ensuring long-lasting engine performance.

Oil Filtration: The Key to Pristine Performance

The oil filter, a seemingly humble component, plays an indispensable role in safeguarding the engines health. By capturing harmful particles, the oil filter prevents premature wear and tear of the cylinderblock and other engine components. Regular oil changes, combined with high-quality oil filters, ensure that your engine operates at its peak potential, minimizing the risk of costly breakdowns.

Advanced Lubrication Systems

Automotive engineers have developed ingenious lubrication systems to cater to the demands of high-performance engines. Variable displacement oil pumps, capable of adjusting oil flow based on engine speed and load, optimize lubrication efficiency, reducing energy consumption and enhancing overall engine performance.

#Cooling: Maintaining Optimal Temperatures

Just as the human body requires a regulated temperature for optimal function, so too does an engine. The cylinderblock, being the heart of the engine, is particularly susceptible to heat buildup. A dedicated cooling system, intricately designed and precisely engineered, ensures that the engine operates within its ideal temperature range.

Liquid Cooling: A Constant Flow of Efficiency

Liquid cooling, the most common approach, utilizes a coolant, typically a mixture of water and antifreeze, to absorb heat from the engine. A water pump circulates the coolant through the engines passages, transferring heat to the radiator, where it is dissipated into the surrounding air.

Advanced Cooling Technologies

In pursuit of enhanced cooling efficiency, engineers have developed a range of innovative technologies. Variable-speed electric water pumps, electronically controlled, adjust coolant flow based on engine demand, optimizing cooling performance while minimizing energy consumption.

#Cylinder Liners: Enhancing Durability and Performance

Cylinder liners, precision-engineered sleeves inserted into the cylinderblock, play a pivotal role in enhancing engine durability and performance. These liners provide a hardened surface that resists wear and tear, extending the lifespan of the cylinderblock and its components. Additionally, cylinder liners improve heat dissipation, ensuring optimal engine operation and longevity.

Wet Liners: A Superior Cooling Solution

Wet liners, surrounded by coolant, offer superior cooling capabilities compared to dry liners. This design ensures uniform heat dissipation, reducing thermal stress on the cylinderblock and its components. Furthermore, wet liners allow for easier maintenance and replacement, reducing downtime and associated costs.

Dry Liners: A Cost-Effective Alternative

Dry liners, pressed directly into the cylinderblock, provide a cost-effective alternative to wet liners. While they offer less efficient cooling, dry liners are suitable for less demanding applications, striking a balance between performance and affordability.

#Cylinder Head: The Engines Breathing Apparatus

The cylinder head, seamlessly bolted to the top of the cylinderblock, forms the combustion chamber and houses the valves that control the intake and exhaust of air and fuel. A complex network of passages within the cylinder head facilitates the flow of coolant and oil, ensuring optimal engine operation.

Overhead Camshaft Design: Enhanced Performance

In an overhead camshaft (OHC) design, the camshaft is positioned in the cylinder head, directly above the valves. This design allows for more precise valve timing and higher engine speeds, resulting in improved performance and fuel efficiency.

Dual Overhead Camshaft Design: Ultimate Control

The dual overhead camshaft (DOHC) design features two camshafts, one for the intake valves and one for the exhaust valves. This configuration provides even greater control over valve timing, maximizing engine performance and efficiency.

#Pistons: The Powerhouse Within

Pistons, reciprocating within the cylinders, are the driving force behind the engines power generation. These meticulously crafted components, typically made of aluminum or steel, are designed to withstand the immense pressures and temperatures encountered during combustion. The shape and design of the pistons play a significant role in determining the engines performance and efficiency.

Piston Rings: Sealing the Combustion Chamber

Piston rings, fitted into grooves on the piston, form a tight seal against the cylinder walls, preventing combustion gases from escaping and ensuring efficient engine operation. These rings also regulate oil flow, minimizing friction and wear.

Piston Design: Optimizing Performance

Piston design has undergone continuous evolution, driven by the pursuit of enhanced engine performance and reduced emissions. Designers have adopted sophisticated techniques such as variable compression ratios, which adjust the pistons position in the cylinder, maximizing efficiency and power output under varying operating conditions.

#Connecting Rods: The Power Transmitters

Connecting rods, vital links between the pistons and the crankshaft, transmit the reciprocating motion of the pistons into rotary motion. These rods are subjected to significant forces during engine operation, requiring exceptional strength and durability.

Forged Connecting Rods: Unmatched Strength

Forged connecting rods, formed through a specialized forging process, offer exceptional strength and durability. This manufacturing technique ensures a homogeneous structure, minimizing the risk of fatigue and failure, making forged rods ideal for high-performance applications.

Lightweight Connecting Rods: Enhancing Efficiency

Lightweight connecting rods, made from materials such as titanium or carbon fiber, reduce the weight of the rotating assembly, minimizing inertial forces. This weight reduction contributes to improved engine efficiency and reduces vibration, enhancing overall engine performance.

#Crankshaft: The Engines Maestro

At the heart of the engine, the crankshaft orchestrates the conversion of reciprocating motion into rotary motion. This meticulously engineered component, often made of forged steel, undergoes rigorous balancing and polishing processes to ensure smooth operation and minimize vibrations.

Crossplane Crankshaft: Balanced Power Delivery

In a crossplane crankshaft design, the crankpins, connecting the crankshaft to the connecting rods, are arranged at 90-degree intervals. This design ensures balanced power delivery and minimizes vibration, resulting in smoother engine operation.

Flat-Plane Crankshaft: Enhanced Performance

A flat-plane crankshaft features crankpins arranged on the same plane, resulting in a distinctive exhaust note and enhanced performance. This design is often found in high-performance engines, where maximizing power output is a primary objective.

#Cylinderblock Inspection: Ensuring Peak Performance

Regular inspection and maintenance are essential to ensure the cylinderblocks longevity and optimal performance. Visual inspections can reveal cracks, leaks, or other abnormalities that may require attention. Specialized tools and techniques, such as borescopes and ultrasonic testing, allow for thorough examination of the cylinderblocks internal surfaces and components.

Ultrasonic Testing: Precise Flaw Detection

Ultrasonic testing utilizes high-frequency sound waves to detect hidden flaws or defects within the cylinderblock. This non-destructive method provides a detailed assessment of the cylinderblocks integrity, ensuring timely detection and repair of any potential issues.

Pressure Testing: Leak Detection and Peace of Mind

Pressure testing involves applying pressurized air or fluid to the cylinderblock to identify leaks or cracks. This procedure ensures that the cylinderblock maintains its integrity and prevents the loss of compression or coolant, ensuring reliable engine operation.

#Real-World Success Stories: Cylinderblocks in Action

The cylinderblocks unwavering performance has been instrumental in countless automotive success stories. From the legendary Ford Flathead V8, renowned for its durability and iconic sound, to the high-revving Honda VTEC engines, known for their exceptional power and efficiency, the cylinderblock has proven its mettle in a wide range of automotive applications.

The Indestructible Ford Flathead V8

Introduced in 1932, the Ford Flathead V8 quickly gained a reputation for its exceptional durability and reliability. This engine, featuring a cast-iron cylinderblock, powered countless Ford vehicles for decades, earning a loyal following among enthusiasts and collectors alike.

The Screaming Honda VTEC

Hondas VTEC (Variable Valve Timing and Lift Electronic Control) technology revolutionized engine design, enabling high-revving performance and impressive fuel efficiency. The VTEC system, integrated with a sophisticated cylinderblock design, allowed Honda engines to deliver both power and economy,